Solve CNC problems for you

The main factors causing spindle imbalance in CNC machine tools are the types of imbalance

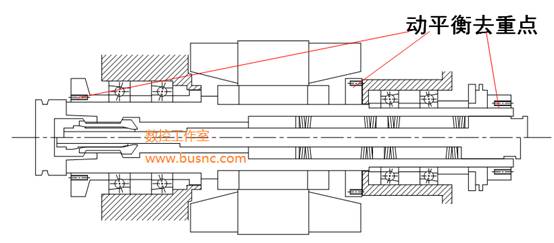

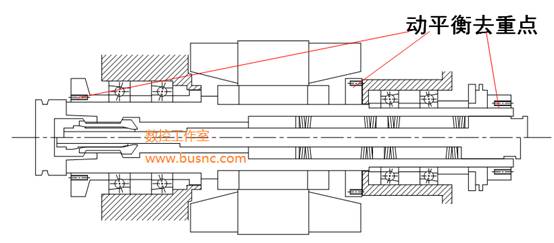

1. & Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; The main factors causing machine tool spindle imbalance

L & Nbsp& Nbsp; The spindle design has asymmetry< Br/>

L & Nbsp& Nbsp; Uneven distribution of spindle material< Br/>

L & Nbsp& Nbsp; There are errors in the process of spindle machining and assembly< Br/>

L & Nbsp& Nbsp; Unbalanced tool structure or wear< Br/>

2. Types of spindle unbalance

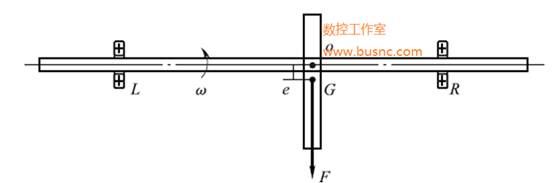

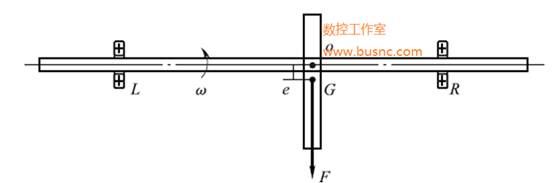

1) Static imbalance

The imbalance of the spindle is only in a state where it deviates from the axis direction at the center of gravity G< Br/>

Using a vector Us that passes through the center of gravity G of the spindle; Represent< Br/>

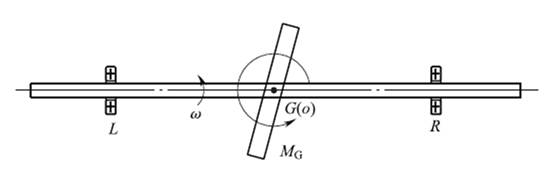

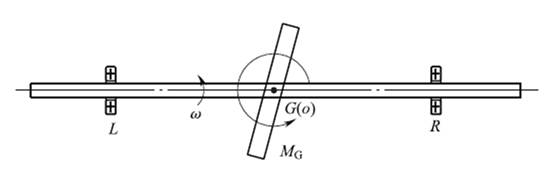

2) Couple imbalance

It is the line connecting the imbalance of the spindle and the axis at the center of gravity G In an intersecting state, the imbalance of the axis of rotation forms a couple of forces around the center of gravity< Br/>

The imbalance of the couple is represented by a pair of vectors Um of the same size but opposite direction< Br/>

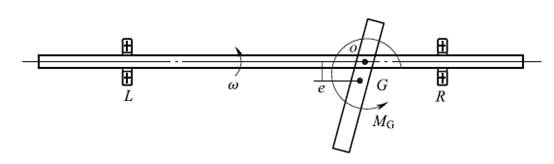

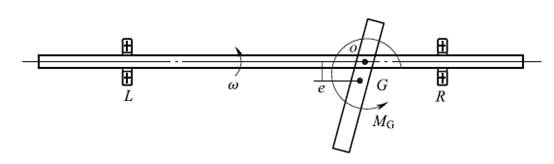

3) Dynamic imbalance

It is a state where the axis is neither parallel nor intersecting with the line connecting the unbalance of the spindle< Br/>

Can be equivalent to a static unbalance quantity Us that is not in the same plane; And an unbalanced amount Um with a force couple< Br/>

4) Quasi static imbalance

It is a special case of dynamic unbalance, where the line connecting the main axis unbalance and the axis is at the center of gravity G An unbalanced state where a point intersects outside. It can be equivalent to a static unbalance and a couple unbalance in the same plane< Br/>