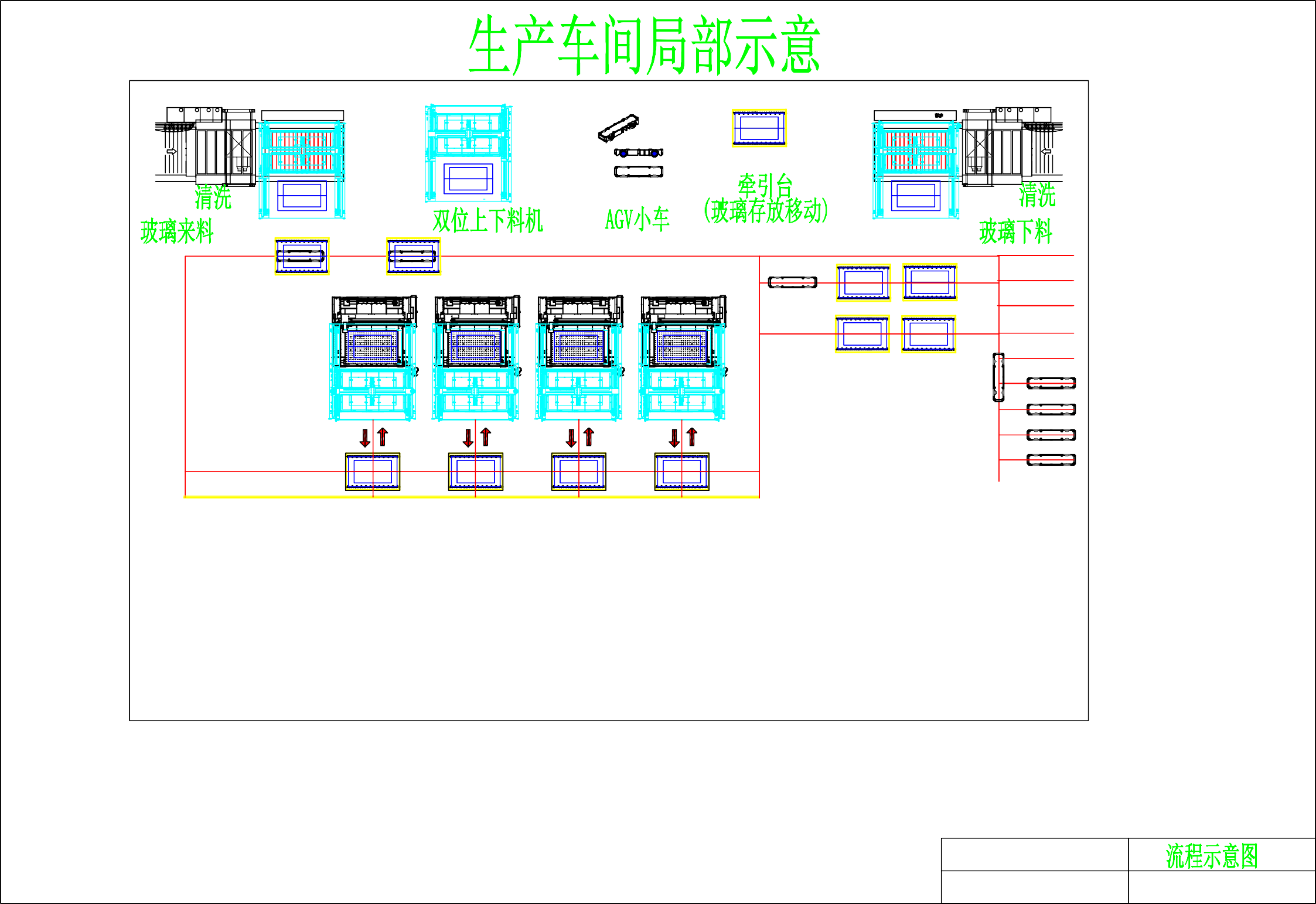

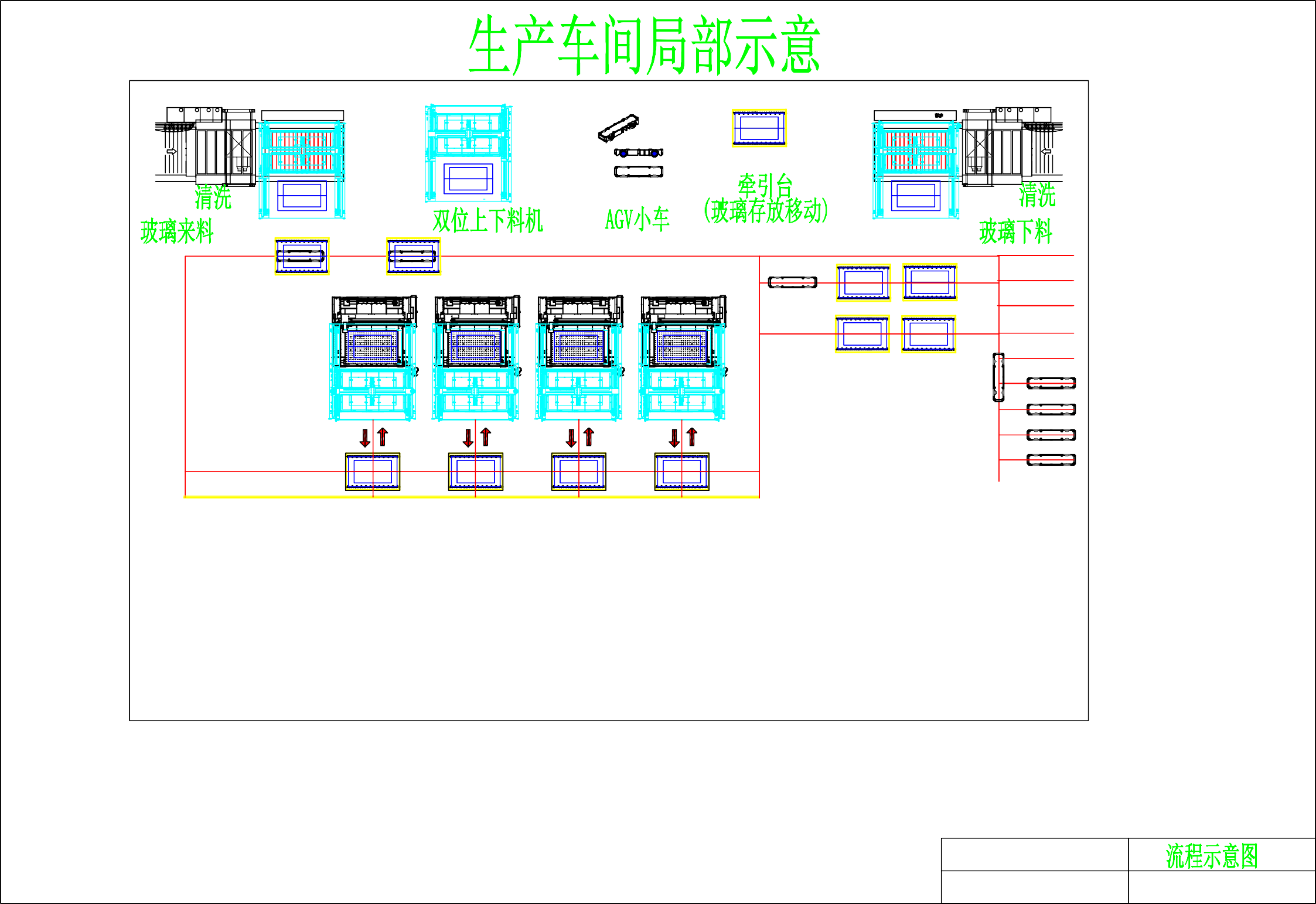

Production line process description:

1. Cleaning discharge - The loading and unloading machine moves the glass to the traction table,

2. The AGV car will transport the glass from the traction platform (load) to the precision carving machine through the trajectory road,

3. The loading and unloading machine above the precision carving machine sucks and moves the glass to the working platform of the precision carving machine. After the material is collected, the AGV car disengages from the traction platform and returns to the standby position for charging or docking with the next traction platform< Br/>

4. The precision carving machine platform automatically positions and clamps, and after completion, moves to the production position (glass precision carving)

5. After glass carving, the carving machine platform moves to the upper and lower material positions, and the mechanical lower material is transported to the traction table. The AGV car pulls the traction table to the upper material position of the rear cleaning machine< Br/>

6. After reaching the loading position of the cleaning machine, the loading and unloading machine moves the glass to the cleaning line for glass cleaning (entering the later stage of the process)