brief introduction

The SD2550 model is a large aluminum profile drilling and machining center specially designed for customers& Nbsp; The motion mode is to move the Y-axis workbench forward and backward, the X-axis machine head moves left and right, and the Z-axis spindle moves up and down.

Taiwan Shengjie 16 position clamp arm tool magazine, with a tool changing speed of 2 seconds, greatly improving production efficiency& Nbsp; Adopting Mitsubishi CNC system; The body is made of cast iron structure; The three-axis adopts Taiwan's Shangyin P-grade linear guide rail, grinding grade ball screw, German coupling, Mitsubishi servo motor, advanced spindle refrigeration system, automatic lubrication system, coolant circulation water spray system, ensuring higher machining accuracy, speed and stability;; Especially suitable for precision engraving, milling, drilling, and tapping of various types of steel, copper, aluminum, acrylic, plastic and other parts& Nbsp;

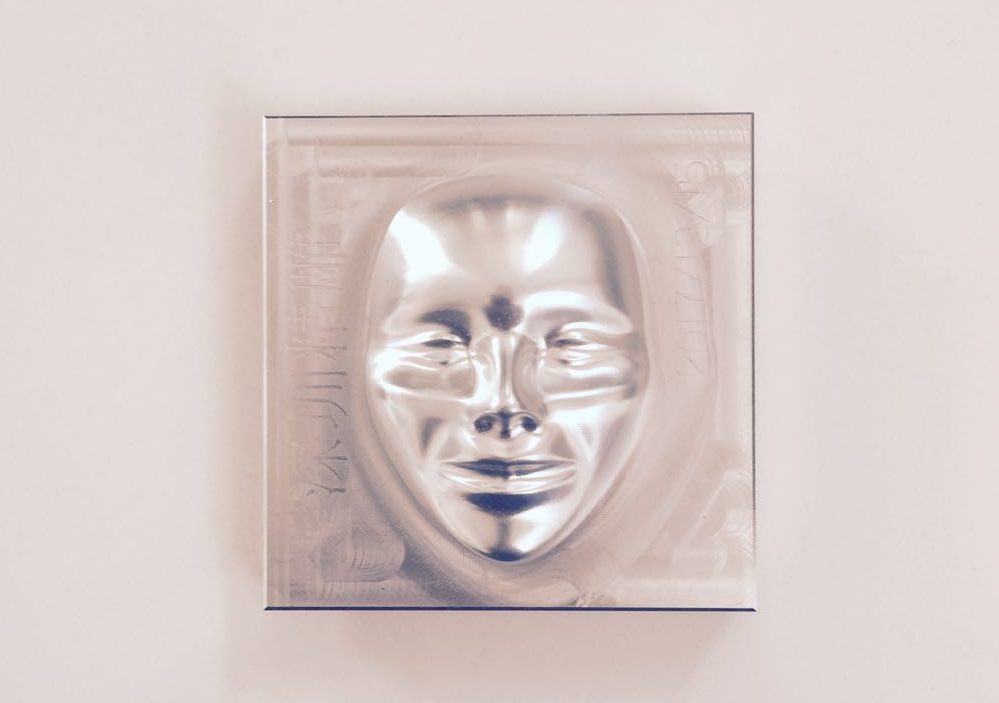

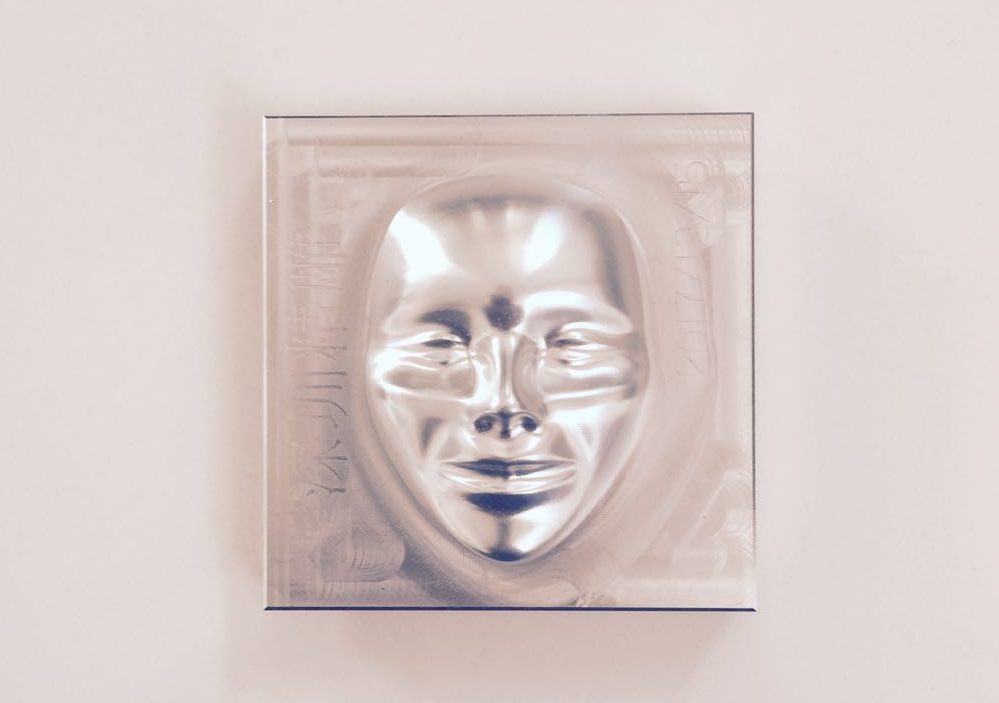

Product rendering (click on the image to have a surprise)

&Nbsp;

nine hundred and one

&Nbsp;

&Nbsp;

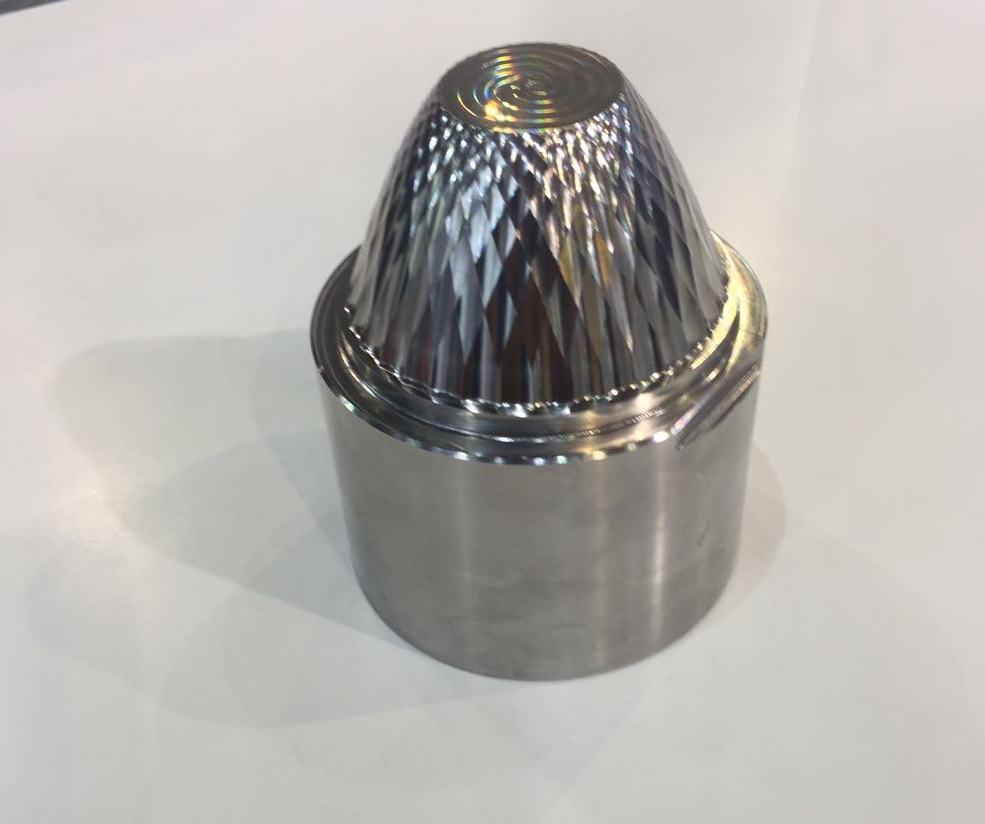

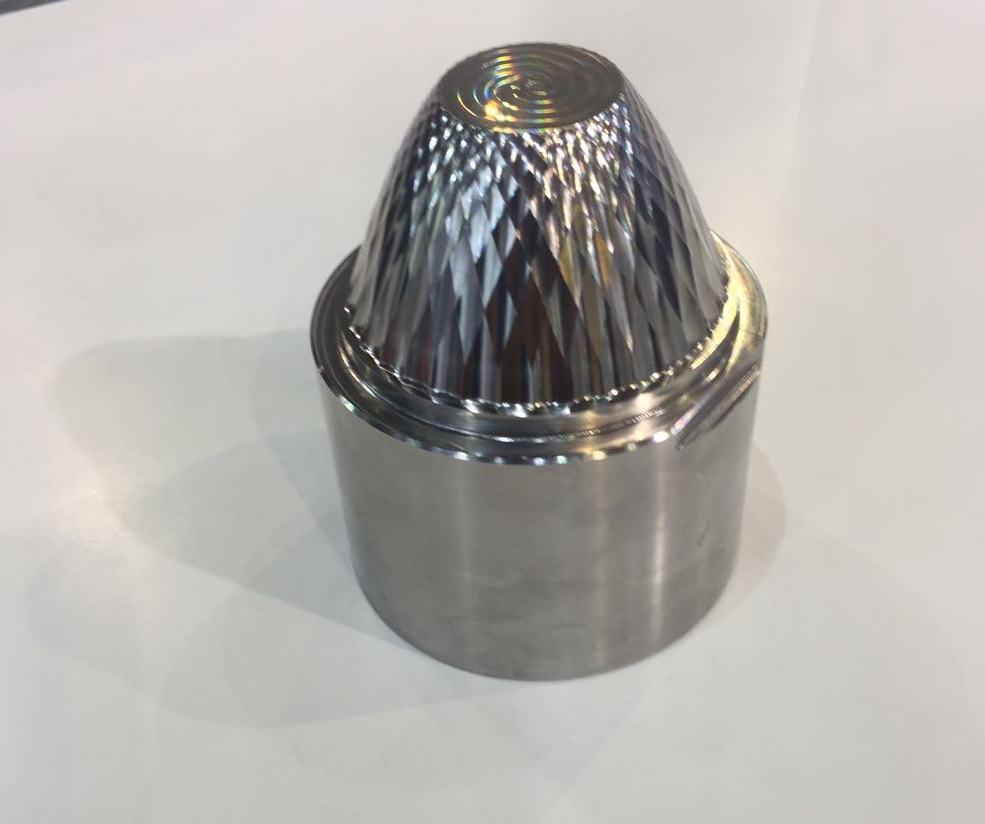

Teeth attack effect

nine hundred and four

List of Main Machine Configuration (Unit: mm)

&Nbsp;

Number

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

gauge

Grid; say

bright

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

quantity

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp. 1

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

Power requirements

17kw 3-phase; 380V± 10% 50/60± 1HZ

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

Total weight (kg)

7000; about

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

Machine tool dimensions (mm) (L× W× H)

4380× 2710× two thousand and five hundred

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

Standard configuration and accessories for the host

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;

&Nbsp;Special precautions for machine tool maintenance

The machine tool is lubricated with thin oil. If the oil level of the lubricating oil pump is too low, an alarm will sound. Add it in a timely manner; 32 No. lubricating oil.

Before using the machine tool for processing in each work shift, run the machine tool spindle using the user provided thermal program; 10 Minutes;

And check to ensure that the spindle air seal, spindle cooling circulation system, and electric box cooling fan operate normally.

Avoid acidic and alkaline substances to prevent corrosion of metals; Before the end of each work shift, it is necessary to clean the chips on the machine tool.

The control panel should be kept clean and wiped regularly to prevent liquid pollutants from entering the interior through gaps and causing short circuits and burning.

The dust filter and cooling fan of the oil cooling machine in the electrical box need to be cleaned every two weeks< Br/>

Shenzhen Jingdiao was established in 2011, and its business scope includes: Jingdiao machines, carving and milling machines, carving machines, glass machines, drilling and tapping machines, highlight machines, automatic loading and unloading machines, robots, etc.

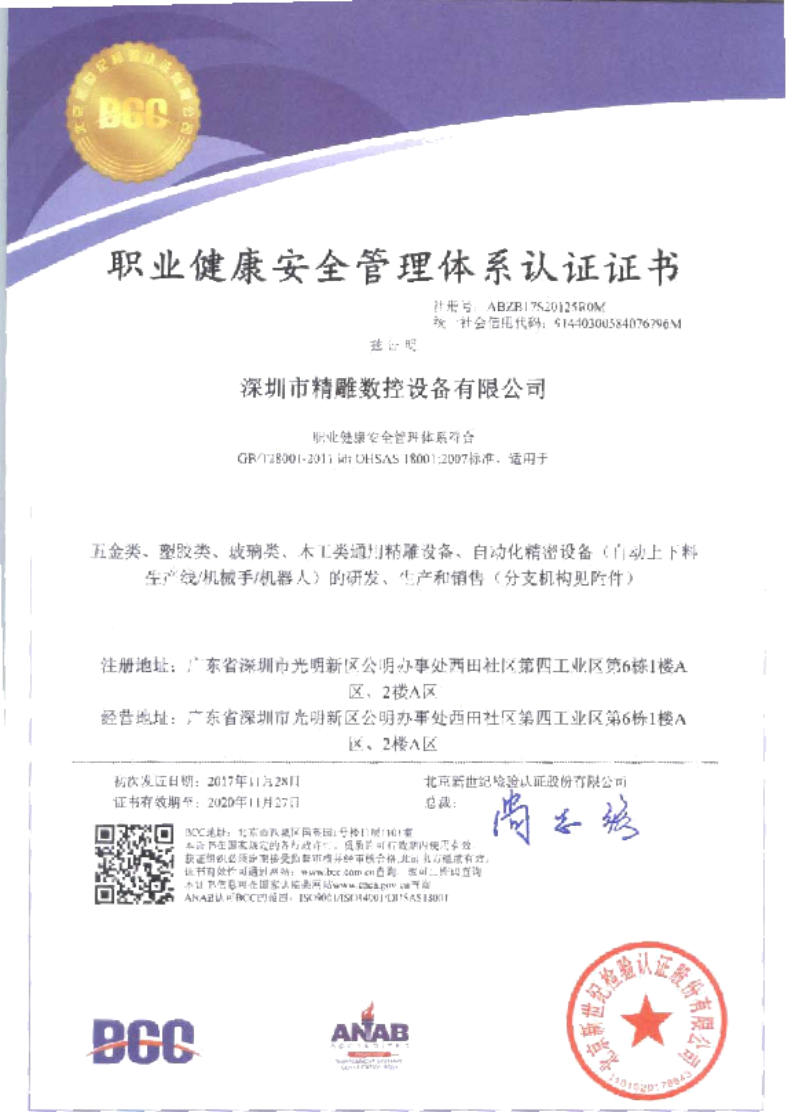

Obtaining three major system certificates in this stage

nine hundred and eight

Mobile phone: 13924586646

Phone: 0755-29423909 [Toll Free: 400-0058-102]

Email: sz_jdsk@163. com

Address: Zone A, Building 6, Fourth Industrial Zone, Xitian Community, Gongming Street Office, Guangming New District, Shenzhen