The changes in metal, glass, ceramics, and mobile phone casing materials have also brought significant opportunities to the processing equipment market, with CNC, precision carving machines, hot bending machines, and die-casting equipment competing on the same platform

Metal phone case

&Nbsp;

&Nbsp;

The market share of metal shells is still large

Since the release of the iPhone 4 in 2010, which showcased metal phone cases to consumers, a large number of phone manufacturers have started using this material, which has also driven the market for metal case processing equipment.

nine hundred

From iPhone 4 to iPhone 6-8, Apple's metal usage is increasing

(Source: ifixit)

&Nbsp;

nine hundred and one

Changes in penetration rate of metal phone cases from 2012 to 2016

(Source: China Industry Information Network)

The metal casing is mainly produced by CNC machine tools

At present, the main processing technologies for mobile phone cases include; Aluminum extrusion+CNC machining& Ldquo; Die casting+CNC machining; And&quo; Stamping+CNC machining; Three ways. No matter which process is used, the processing of metal shells cannot be separated from CNC equipment.

nine hundred and two

Three processing techniques and their characteristics for the metal casing of mobile phones

Market demand for high-speed drilling machine tools

In CNC machining equipment for mobile phone casings, high-speed drilling and tapping machines are one of the most important production equipment. The efficiency of high-speed drilling and tapping centers is higher, ten times that of ordinary machining centers, so high-speed drilling and tapping machines are often used in the production of mobile phone cases.

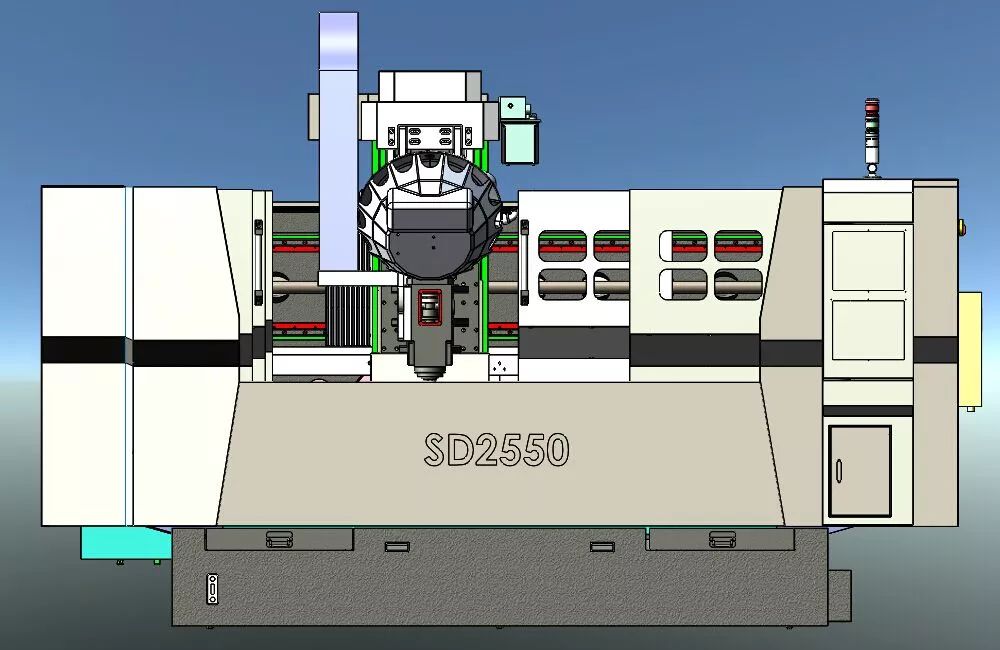

nine hundred and three

nine hundred and four

Schematic diagram of high-speed drilling and tapping machine tool

(Source: Shenzhen Precision Sculpture Machinery)

At present, the production capacity of drilling and drilling machine tools just meets the downstream market demand. According to a processing time of 60 minutes for a mobile phone case, with an 80% crop yield and a 50% pass rate, the production capacity of metal mobile phones supported by each thousand drilling and tapping machines is 2

7" data-s="300,640" data-type="jpeg" data-w="778" src="https://mmbiz.qpic.cn/mmbiz_jpg/273IlP6bI5HYXm74Pq6TLqsgWdasSQEM9xGgicibF0ib171yfaTWLvnzvCcnKFicw39KjcYQjnBGpent4M4WSRGiaVw/0?wx_fmt=jpeg" style="margin: 0px; padding: 0px; height: auto !important; max-width: 100%; box-sizing: border-box !important; word-wrap: break-word !important; width: auto !important; visibility: visible !important;" />00 per month.

nine hundred and five

The installed capacity of CNC drilling centers can only meet the current market demand (2015)

(Source: TrendForce)

The growth of mobile phone sales is due to000 units, with an additional market space of approximately 2 billion yuan.

Domestic related equipment enterprises

nine thousand and eighteen

liquid metal

&Nbsp;

&Nbsp;

Performance and advantages

Liquid metal is an amorphous alloy with a molecular structure different from the crystalline structure of traditional metals, similar to the molecular structure of glass, commonly known as "; Metal glass;.

&Nbsp;

nine thousand and nineteen

Liquid metal combines the excellent mechanical properties of metals with the easy forming and processing characteristics of glass. It has the characteristics of high strength, high hardness, good elasticity, corrosion resistance, and low melting point, making it easy to process plasticity. Specifically, liquid metal processing can be formed in one go without the need for tedious post-processing procedures to obtain products that are close to their intended use.

nine thousand and twenty

Significant improvement in the strength of liquid metal

nine thousand and twenty-one

Significant increase in hardness of liquid metal

application

At present, Omega watches have used liquid metal on the case; The SIM card slot of iPhone has already started using liquid metal. Some high-end skis and golf ball heads also use liquid metal products.

nine thousand and twenty-two

Schematic diagram of liquid metal die-casting machine

Processing equipment

In liquid metal processing equipment, vacuum die-casting machines account for the largest proportion of investment. Taking the fundraising project of Taiyi Yingtuo's liquid metal production line as an example, it aims to produce liquid metal products within 4 years of reaching the production deadline1107600 pieces, with equipment investment of about 300 million yuan, of which vacuum die-casting machine investment is about 217 million yuan, accounting for 73%.

nine thousand and twenty-three

The proportion of liquid metal processing equipment